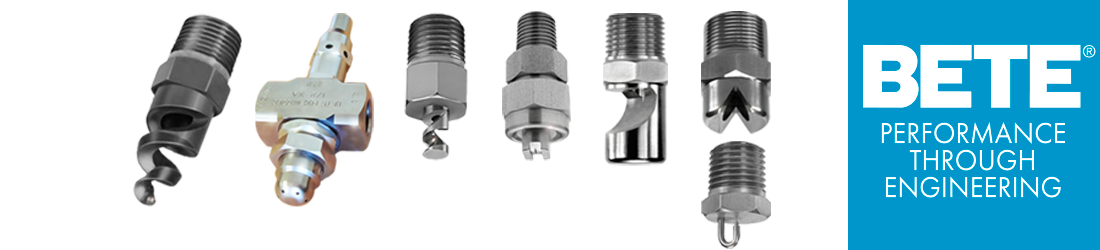

Nozzle Features

- Effective, economical way to circulate liquids in closed or open tanks

- Flow rates from 26.7L/Min to 12000 L/Min

- Inherently clog-resistant

- Nozzle operation creates a multiplying effect on fluid flow; the volume of discharge liquid will be 3-5 times greater than the motive liquid pumped

- Cone-shaped plume