Working principle

The Gamajet range of high impact tank cleaning devices combine pressure and flow to create high impact cleaning jets. Cleaning occurs at the point at which the concentrated stream impacts the surface. It is this impact and the tangential force that radiates from that point which blasts contaminants from the surface, scouring the tank interior. In conjunction with this impact, the device is engineered to rotate in a precise, repeatable and reliable, 360° pattern. This full-coverage, global indexing pattern ensures the entire tank interior is cleaned, every time.

Cost-effective impingement tank and tote cleaning

A quantum leap in-tank cleaner durability, efficiency, and price, the Gamajet 9 is a totally new tank cleaning system. The Gamajet 9 tank cleaning machine offers compact cleaning for small and mid-sized tanks with fewer parts, and a highly durable design, providing superior performance at an affordable price, making it the ultimate tote washer. Fewer parts mean fewer breakdowns and lower maintenance costs. Coupled with our renowned product quality, the revolutionary Gamajet 9 tank cleaning Machine designed-in durability allows its use in rugged applications in the harshest environments.

The Gamajet 9, like other Gamajets, is a high-quality tank cleaning machine. Originally designed for tote cleaning applications, the Gamajet 9 tank cleaning machine is also perfect for other small and mid-sized tank cleaning applications. Its 360° spray pattern provides thorough scouring of the entire tank or tote, reducing operating time and costs. At an unbelievably low price, the Gamajet 9 tank cleaning machine sets the standard for cost-effective impingement tank cleaning and tote washing.

Features and Benefits:

- Cleans totes and other vessels in under 4-12 minutes

- Powerful: 12 lbs (5.5 kg) of cleaning force at 10’ (3 m)

- Capable of removing latex paint from a polyurethane tote

- Compact, durable and easy to maintain

Lubricant . . . . . . . . . . . . . . . . . . . Food grade

Max. throw length . . . . . . . . . . . . . 1.2 – 6 m

Pressure

Working pressure . . . . . . . . . . . . . . 3 – 70 bar

Recommended pressure . . . . . . . . . 4 – 40 bar

Materials

1.4404 (316L), PPS, PTFE, FKM (EPDM and FFKM available).

Temperature

Max. working temperature . . . . . . . . 95°C

Max. ambient temperature . . . . . . . . 140°C

Weight . . . . . . . . . . . . . . . . . . . . . 2.2kg

Connections

Standard thread . . . . . . . . . . . . . . . ¾” Rp NPT, female/ 1 ¼” camlock

Available option . . . . . . . . . . . . . . . ¾” BSP, female/ 1 ¼” camlock, 1 ½” tube weld on

Options

Electronic rotation sensor to verify 3D coverage.

Caution

Do not use for gas evacuation or air dispersion.

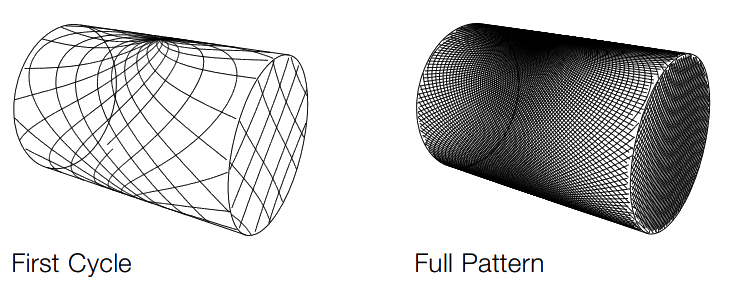

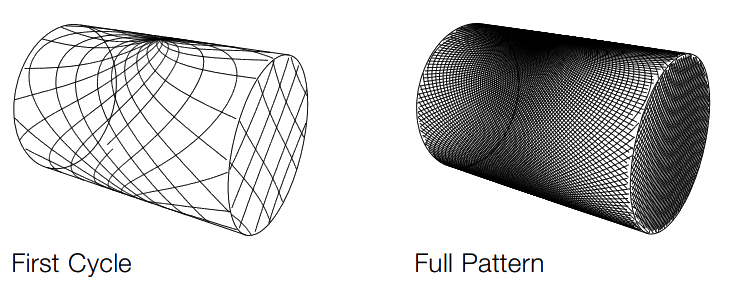

Cleaning Pattern

The above drawings show the cleaning pattern achieved on a cylindrical horizontal vessel. The difference between the first cycle and the full pattern represents the number of additional cycles available to increase the density of the cleaning.