Working principle

The Gamajet range of high impact tank cleaning devices combine pressure and flow to create high impact cleaning jets. Cleaning occurs at the point at which the concentrated stream impacts the surface. It is this impact and the tangential force that radiates from that point which blasts contaminants from the surface, scouring the tank interior. In conjunction with this impact, the device is engineered to rotate in a precise, repeatable and reliable, 360° pattern. This full-coverage, global indexing pattern ensures the entire tank interior is cleaned, every time.

Lubricant . . . . . . . . . . . . . . . . . . . Food grade

Max. throw length . . . . . . . . . . . . . 30.5 m

Pressure

Working pressure . . . . . . . . . . . . . . 3 – 21 bar

Recommended pressure . . . . . . . . . 3.5 – 14 bar

Certificate

2.1 material certificate

Materials

1.4404 (316L), PPS, FKM (EPDM and FFKM available)

Temperature

Max. working temperature . . . . . . . . 95°C

Max. ambient temperature . . . . . . . . 140°C

Weight . . . . . . . . . . . . . . . . . . . . . 12.7 – 13.2kg

Connections

Standard thread . . . . . . . . . . . . . . . 2” BSP, 2” NPT, female

Options

Electronic rotation sensor to verify 3D coverage. 180° and 105°

directional version available.

Caution

Do not use for gas evacuation or air dispersion.

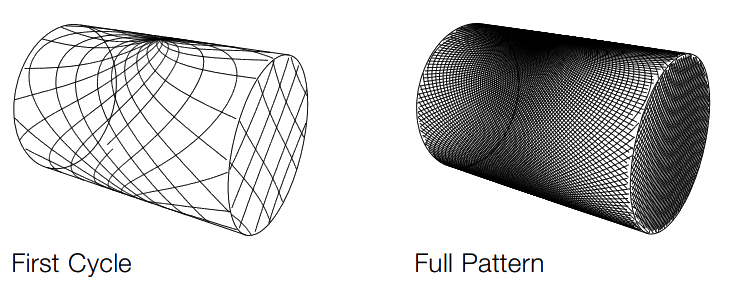

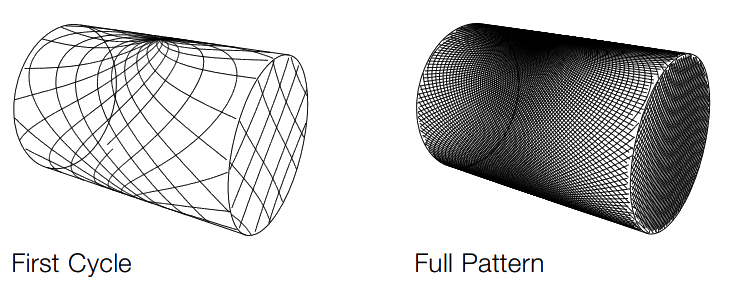

Cleaning Pattern

The above drawings show the cleaning pattern achieved on a cylindrical horizontal vessel. The difference between the first cycle and the full pattern represents the number of additional cycles available to increase the density of the cleaning.