Working principle

The Gamajet range of high impact tank cleaning devices combine pressure and flow to create high impact cleaning jets. Cleaning occurs at the point at which the concentrated stream impacts the surface. It is this impact and the tangential force that radiates from that point which blasts contaminants from the surface, scouring the tank interior. In conjunction with this impact, the device is engineered to rotate in a precise, repeatable and reliable, 360° pattern. This full-coverage, global indexing pattern ensures the entire tank interior is cleaned, every time.

Powerful, sanitary tank cleaning for a variety of pressures and flows

The Gamajet PF tank cleaning machine was specifically engineered to offer the most efficient and effective cleaning for vessels with capacities of 5,000 to 25,000 gallons. The durable machine offers optimal cleaning at a variety of pressures and flows. The sanitary design of the Gamajet PF makes it ideal for use in food & beverage, pharmaceutical and personal care industries, for both portable and permanent applications. The standard machine is self-cleaning, self-flushing, and self-lubricating, requiring no oil or grease in the gear train. However, a grease-lubricated version is available as an option. All components of the PowerFlex are made from FDA compliant materials.

The key to the Gamajet PF’s versatility and durability is the use of an oversized gear head that efficiently generates the proper torque to rotate the unit. The larger components last 20-30% longer than traditional drive mechanisms, making the Gamajet PF our most durable design to date. The large gear reduction allows the Gamajet PF to operate at lower pressures and higher flows when compared to other tank cleaning machines. Like other Gamajet tank cleaning machines, the Gamajet PF uses the same proven Gamajet impingement cleaning pattern, scouring 100% of the tank, every time.

Features and Benefits:

- Sanitary design

- Operates at lower pressures

- Powerful: 25 lbs (11.5 kg) of cleaning force at 25′ (7.5 m)

- Available in flow-through or grease-lubricated design

Lubricant . . . . . . . . . . . . . . . . . . . Food grade

Max. throw length . . . . . . . . . . . . . 14 – 26 m

Pressure

Working pressure . . . . . . . . . . . . . . 3.0 – 28.0+ bar

Recommended pressure . . . . . . . . . 4 – 20 bar

Certificate

2.1 material certificate

Materials

316L, PPS, PTFE, EPDM (FKM and FFKM available).

Temperature

Max. working temperature . . . . . . . . 90°C

Max. ambient temperature . . . . . . . . 140°C

Weight . . . . . . . . . . . . . . . . . . . . . 4.5 kg

Surface finish . . . . . . . . . . . . . . . . 0.8 µm32 Ra

Connections

Standard thread . . . . . . . . . . . . . . . 1½” (BSP) or NPT, female

Available option . . . . . . . . . . . . . . . 1.5” weld, 1.5” tri-clamp, 1.5”

Options

Electronic rotation sensor to verify 3D coverage.

Caution

Do not use for gas evacuation or air dispersion.

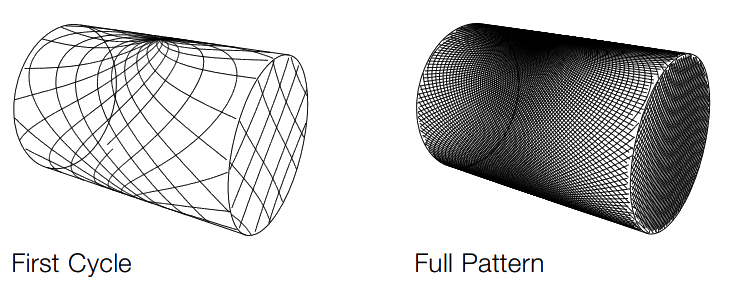

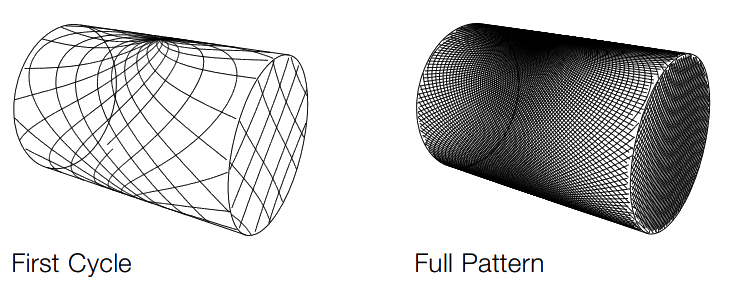

Cleaning Pattern

The above drawings show the cleaning pattern achieved on a cylindrical horizontal vessel. The difference between the first cycle and the full pattern represents the number of additional cycles available to increase the density of the cleaning.