Where to Find Premier Spray Chilling Carcass Nozzles in New Zealand

Spray chilling carcass nozzles are essential in the meat processing industry.

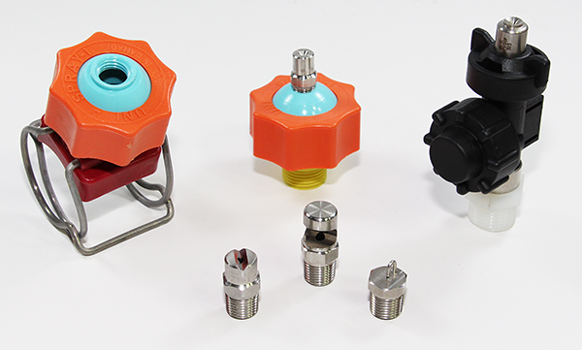

For those in the meat industry who need spray chilling carcass nozzles, Spray Nozzle Engineering is the place to turn. With options for spray chilling nozzles, Silvent Nozzles, and general industrial nozzles, we have the ideal products for your purposes.

Options We Provide for Food Services Beyond Spray Chilling Carcass Nozzles

As the industrial spray nozzle authorities, we offer a variety of products for food industries such as:

- Spray Dry Nozzles: Our Click&Dry nozzles make a hygienic choice for anyone in dairy processing plants or other food manufacturing services.

- Strahman Valves: These valves are used in beverage and dairy services, perfect for washing down and pre-rinsing your valued equipment.

- Carcass Chilling Nozzles: In the meat industry, the right carcass chilling nozzle will make a huge difference to preserve your final product.

Why the Right Spray Chilling Carcass Nozzles Make a Significant Difference

Ensuring you get the correct spray chilling nozzles makes a significant impact on your operation and can afford benefits such as:

- Energy Savings: The right nozzle will increase energy efficiency.

- Increased Production: A well-functioning nozzle will increase your productivity.

- Better Hygiene: Our chilling nozzles are a hygienic, clean option for your operation.

- In built system checks that the valve has stopped dripping after spray completion.

As Australia’s leading industry nozzle experts, we seek to get you what you need when you need it. Get in touch to find out more, or to ask any questions you may have.