Spray Nozzle Engineering offers solutions for the pharmaceutical and parapharmaceutical industries. Whether dry or wet, tablets or injectables, personal care or veterinarian and animal health products, Spray Nozzle has a product or system to assist in better process outcomes.

Spray Nozzle Engineering supplies products for use on all parts of the system:

- Raw material batching and blending

- Distribution and coating

- Spray drying

- Batch CIP cleaning systems

- Packaging aids such as air knives and blowing

Spray drying is a specialist area that is covered by our unique engineered and patented products. The Click & Dry series of Spray Dry Nozzles is a common method used to dry many temperature-sensitive materials like foods, chemicals and pharmaceuticals. Spray Nozzle Engineering offers Click&Dry spray nozzles in many configurations to suit your application and were the first to design a nozzle specifically for improved spray dry nozzle hygiene; called Hygiene Plus.

The company also manufactures the M-series Tank Cleaning nozzles. Ideal for tank and VAT cleaning in the pharmaceutical industry, the M-Series can be specified with full material traceability and part ID Number identification, to use as part of your validation process.

Our nozzles and product range are suitable for:

- Spray Drying

- Washdown an foam applications

- Spraying and Coating

- Cleaning

- Lubrication

- Blowing

- Sanitising

- Tank cleaning (CIP)

- Drying and blowing

-

Strahman swivel adapters in brass and stainless steel

Available swivels to keep your Strahman hoses and nozzles operating properly. -

Strahman swivel adapters in brass and stainless steel

Available swivels to keep your Strahman hoses and nozzles operating properly. -

Features:

- Water-saving trigger nozzles

- Heavy-duty protective covers & bumpers

- Bronze & stainless steel construction

- The flat fan spray pattern

- Trigger controlled

- Optional swivel attachments available

-

Lafferty chemical transfer systems use compressed air operated double diaphragm pumps to transfer chemical concentrates or ready-to-use solution from bulk containers to any other container.

-

The partnership of Spray Nozzle Engineering and Reel Tech gives you total fluid solutions. Our partnership allows us to supply safer and innovative CIP Tank cleaner and hose reel systems to meet the exact needs of the client. Our technology eliminates confined space entry hazards for personnel, manual handling of large and long lengths of CIP (Clean-in-place) hose, and fixed CIP Lances. Reel Tech Reels are designed with safer rewind speeds, explosion-proof motors and can be integrated into PLC systems for fully automated washing. Our CIP rotating nozzles from SNE reduce CIP cycle times, water and chemical usage and turn around times, saving time and money whilst delivering safer cleaning solutions. Our reel technology also extends to bulk delivery-decanting and other food transfer and washdown applications requiring hose storage solutions.

-

Need to clean the bottom of a tank fast and effectively? Look no further than the NEW Gamajet Bullet IV for tough, targeted cleaning of sludge, oil, grease, fat, and other residual debris that collects at the bottom of open-top tanks, process vessels, trailers, barges, and rail cars. The Gamajet Bullet IV rotates in a tight 105-degree downward pattern, with high impact water jets scouring the bottom area of the tank. Built with durability, strength, and performance in mind, residual heels don't stand a chance against this machine. Eliminate:

- sludge build-up

- upsplash/oversplash

- excessive water usage

- confined space entry for manual cleaning

-

Features:

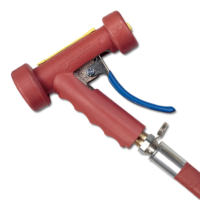

Our F-90 Series has the same great features as our M-70 Series, such as:- Available in Bronze or Stainless Steel

- Comfortable long handle design grip for whole hand placement

- Replaceable heavy-duty rubber covers in a choice of Black, White, or Red

- Stainless Steel seat design prevents nozzle seat leakage

- Instant water shut-off when the trigger is released

- Adapters available in Barbed Rigid and Swivel, and female GHT

- The maximum working pressure is 150psi (10BAR)

- Maximum operating temperature of 200ºF (93ºC)

-

Foamers are chemical applicators that project clinging foam onto surfaces up close or at a distance. Foamers are available in a variety of configurations and with flow rates. Viral or bacterial contamination is an ongoing problem during food production processes. The Lafferty series of compressed air venturi foamers (LC Foamer) provide food manufacturers with chemical application equipment that ensure a complete clean along with reliable performance and cost savings.

-

Application

The Alfa Laval GJ 10 tank cleaning device fits through a 10.16 cm (4”) opening and is capable of cleaning a 113.56 liter (30,000 gal) underground fuel storage tank with one insertion. This device blasts away contaminants and breaks up dirt and sludge in minutes. The Alfa Laval GJ 10 easily converts the contaminant-laden sludge into a solution which allows for complete liquid extraction and thorough tank cleaning. The device is part of the world-renowned Gamajet range of tank cleaning devices. -

Application

The Alfa Laval GJ 4 is part of the world-renowned Gamajet range of high impact tank cleaning devices. The device provides high-impact cleaning for large-sized tanks with diameters over 4.6 m (15’). This device is fully capable of high-concentration chemical recirculation cleaning and high-pressure, low-volume water jet scrubbing in fixed, automated CIP systems. The Alfa Laval GJ 4 is designed to remove the toughest residues from large tanks in numerous industries and is customizable in a wide variety of ways. The Alfa Laval GJ 4 allows companies to spend less time cleaning and more time producing. -

Application

The Alfa Laval GJ 5 offers compact cleaning for small-sized tanks, vats, and vessels. This device is designed for cleaning tanks 4.6 m (15 ft.) in diameter by 4.6 m (15 ft.) high and can easily fit through 7.62 cm (3 in.) openings. By switching from costly manual cleaning and time-intensive spray balls to the Alfa Laval GJ 5, companies are able to save a substantial amount of time, water, and money. The device is part of the world-renowned Gamajet range of high impact tank cleaning devices. -

Application Designed with ergonomics in mind, the Alfa Laval GJ 8 provides the same high impact clean as traditional, larger tank cleaners but is lighter, shorter, and narrower. This device is part of the world-renowned Gamajet range of high impact tank cleaning devices and is the perfect alternative to heavy impingement cleaners, time-intensive spray balls, and costly manual tank cleaning. Compact and efficient, the Alfa Laval GJ 8 allows for space-saving while maintaining the impact, durability, and range required for optimal impingement tank cleaning. This device is fluid-driven, eliminating the need for power assistance and is ideal for cleaning stubborn residues in large tanks in a variety of industries such as ethanol, paper, pulp, chemical, steel, industrial fermentation and many more applications requiring high impact cleaning. A 180 degrees directional nozzle also available.

-

Application

The Alfa Laval Gamajet 9.2 tank cleaning device fits through a 50 mm (2") opening and is capable of cleaning above- and below ground fuel storage tanks with capacities up to 4,750 I (1,2 50 gallons). This device blasts away contaminants and breaks up dirt and sludge in minutes. Diesel fuel can be used as the cleaning agent, which saves time and mitigates contamination and waste disposal. -

Application

Designed to fit through a 2” (5.08 cm) sanitary fitting, the Alfa Laval GJ A2 is part of the world-renowned Gamajet range of high impact tank cleaning devices. It is the perfect alternative to time-intensive spray balls and costly manual cleaning. Made of FDA compliant materials, this device is flow-through in design, meaning it requires no grease or oil in the gears. Compact and efficient, the Alfa Laval GJ A2 allows for space saving while maintaining the impact, durability, and range required for optimal rotary impingement tank cleaning in sanitary environments. -

Application

The Gamajet tank cleaning product range is world-renowned for setting high standards for cleanliness to enable companies to sustain high product quality and plant productivity. As part of that range, the Alfa Laval GJ A6 tank cleaning device delivers powerful tank cleaning that provides reliable, repeatable, and verifiable results to meet the demands of the pharmaceutical, personal care, beverage, food, and dairy industries. Designed to fit through a 3” (7.62 cm) sanitary fitting, the device is ready for permanent installation and is the perfect alternative to time-intensive spray balls and costly manual tank cleaning. -

The Lightest, Most Powerful, Large Tank Cleaner

The E-Z8 provides the SAME flow as traditional, larger tank cleaners, but this new unit is lighter, shorter, and narrower for much easier entry and maneuverability and offers unparalleled ease of handling in a wide variety of tank cleaning applications.

Smaller in diameter than any other fluid-driven unit with similar flow characteristics the E-Z8 does not require any power assists. It fits through small openings while maintaining the flow required to clean larger vessels and its lightweight and smaller size makes it easy to move and handle.

The versatility of this machine when it comes to pressure and flow make it ideal for most large tank cleaning applications.

-

Application

The Alfa Laval GJ BB is part of the world-renowned Gamajet range of tank cleaning devices. With a single insertion of the Alfa Laval GJ BB, barrels and 208.2 l (55 gal) drums are cleaned in only 2-3 minutes while using only 30-45 l (8-12 gal) of water. This device offers high-performance cleaning combined with maximum durability. A heavy-duty stainless steel gear train remains outside the barrel or drum during cleaning, ensuring a long service life. The Alfa Laval GJ BB saves companies substantial amounts of time, water, and money. -

Clean empty your barrels from the Top

The new All-In-One Cleaning Machine combines high-performance impingement cleaning with integrated vacuum extraction, which now allows all shapes and sizes of tanks without drains to be easily cleaned and emptied from the top.

The All-In-One features rotary impingement cleaning technology for exceptional performance, along with an integrated vacuum extractor which removes the cleaning liquid from within the vessel. The lightweight, hand-held machine is designed for operation at flow rates as low as 11.35 lpm. And, unlike other machines, the unit applies 100% of the water flow to cleaning - not in powering the unit itself. With a single insertion of the easily handled unit, 100% cleaning effectiveness along with completer liquid extraction, is assured.

As its name implies, the new All-In-One includes everything needed to easily clean and empty drain-less containers. No other cleaning method provides the convenience, power and low flow capabilities of the All-In-One.

-

Application

The field-proven Alfa Laval GJ PF is part of the world-renowned range of Gamajet high impact tank cleaning devices. This tank cleaning device is designed to be flow-through, meaning no lubricant can pass through the gear train. It has been proven to provide companies with up to 85% in water, time, energy, and resource savings compared to static spray balls. This device is capable of cleaning tanks with capacities between 18.9 m³ - 94.6 m³ (5,000-25,000 gallons). The Alfa Laval GJ PF fits through openings as small as 10 cm (4”) and operates at low pressures and flows, cleaning tanks in the ethanol, paper, pulp, chemical, steel, industrial fermentation industry, and many other applications that require high impact cleaning. By implementing this device into their tank cleaning process, companies spend less time cleaning and more time producing. -

Application

The field-proven Alfa Laval GJ PF is part of the world-renowned range of Gamajet high impact tank cleaning devices. It has been proven to provide companies with up to 85% in water, time, energy, and resource savings compared to static spray balls. This device is capable of cleaning tanks with capacities between 18.9 m³ - 94.6 m³5,000-25,000 gallons. The Alfa Laval GJ PF fits through openings as small as 10 cm4” and operates at low pressures and flows, cleaning tanks in the ethanol, paper, pulp, chemical, steel, industrial fermentation industry, and many other applications that require high impact cleaning. By implementing this device into their tank cleaning process, companies spend less time cleaning and more time producing. -

Features:

- Water-saving trigger nozzles

- Heavy duty protective covers & bumpers

- Bronze & stainless steel construction

- Variable spray patterns, trigger controlled

- Optional swivel attachments available

- Various colours to match HACCP zones

-

Features:

- Water-saving trigger nozzles

- Heavy-duty protective covers & bumpers

- Bronze & stainless steel construction

- Variable spray patterns, trigger controlled

- Optional swivel attachments available

- Durable impact-resistant molded handle

-

Hose-End Foamers and Sprayers are water-driven applicators that dilute chemical concentrate from an attached bottle or other container and project clinging foam.

-

Features:

- Water-saving twist nozzles

- Heavy duty rubber protective covers & bumpers

- Stainless steel construction

- Variable spray patterns, twist control

- Optional swivel attachments available

- Colour coded

Max. Pressure Max. Flow Max. Temperature Inlet 10.3 BAR 140 l/min 75°C 1/2" BSPF Larger flow and thread sizes are available on request

Order Part Number Material Colour TM-HSAN-100-BL Stainless Steel Blue TM-HSAN-100-RE Stainless Steel Red TM-HSAN-100-WH Stainless Steel White -

Features:

- Water-saving trigger nozzles

- Heavy duty protective covers & bumpers

- Bronze & stainless steel construction

- Variable spray patterns, trigger controlled

- Optional swivel attachments available

- Various colours to match HACCP zones

Max. Pressure Max. Flow Max. Temperature Inlet 10 Bar 36 LPM 60°C 1/2" BSPF Order Part Number Material Colour TM-HSBB-200-BL Stainless-Steel Blue -

Features:

- Water-saving trigger nozzles

- Heavy duty protective covers & bumpers

- Bronze & stainless steel construction

- Variable spray patterns, trigger controlled

- Optional swivel attachments available

- Various colours to match HACCP zones

Max. Pressure Max. Flow Max. Temperature Inlet 10 Bar 36 LPM 60°C 1/2" BSPF Order Part Number Material Colour TM-HSBB-300-BL Stainless-Steel Blue -

Hydro-Pro 150® is the most advanced spray nozzle, featuring a patented, locking trigger mechanism that allows users to lock in the desired spray pattern without having to maintain pressure on the trigger. It also reduces misdirected spraying.

Max. Pressure Max. Flow Max. Temperature 10 BAR 35 l/min 93°C Available in Black, Red and White; with or without swivel adapter

Order Part Number

Material

Colour

HP-150-BK

Stainless Steel

Black

HP-150-RE

Stainless Steel

Red

HP-150-WH

Stainless Steel

White

NOTE: Intended for water use only. Not suitable for steam service. Can be used with Strahman steam/water mixers

-

Strahman Hydro-Pro 150® LOW FLOW washdown trigger gun gives you all of the same features of the standard Hydro-Pro 150® nozzle, but you quickly see a reduction in water consumption (40% at 700kpa) and the savings that are sure to go along with it! Constructed with a stainless steel housing for strength and durability, yet this solid, water saver nozzle weighs less than 1 kg. and is ergonomically designed to reduce user fatigue. In addition to being extremely lightweight, the HP-150 features a PATENTED locking trigger mechanism that allows users to lock in the desired spray pattern without having to maintain pressure on the trigger. It also reduces misdirected spraying. The waterproof nylon cover resists cracks, and abrasions and is long-lasting. This spray nozzle is available in three colours – black, white and red. Swivel adapters are available in both standard and Strahman's ergonomic Swivel-Pro range along with a full range of hose options.

-

The M-144TG Bronze Safety Mixing Unit, which was recently redesigned with the latest innovations, will blend steam and cold water in any desired proportion. It is user-adjustable with a factory-set maximum temperature and features a safety shut-off that prevents the passing of live steam. The unit also features a specially designed blending chamber to thoroughly and evenly blend the steam and cold water. The M-144TG Series is equipped with a dial-type gauge that accurately indicates the wash water’s exact temperature. We recommend the M-144TG be purchased as a complete washdown system with a Strahman hose assembly with an automatic shut-off nozzle in order to achieve maximum efficiency and safety. All units now include a Direct Diffuse Steam Trap.

-

The Strahman M-159 Hot & Cold Water Mixing Station enables the operator to manually regulate water temperature as needed for the washdown application via independent controls. Similar to our model M-159TG but without the temperature gauge, our model M-159 is the economical unit for washdown applications where the precise temperature of hot and cold water is not critical for the application. Manually turn the valves for a steady supply of water. A specially designed blending chamber efficiently blends the hot and cold water for maximum performance.

-

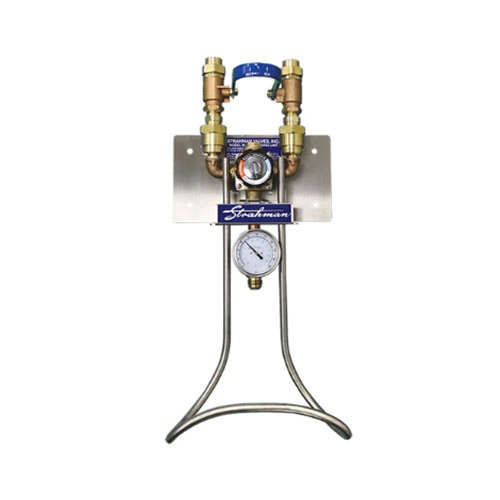

Model M-159TG is ideal for situations where the exact water temperature is crucial for the washdown application since it is equipped with a dial-type temperature gauge (TG) that indicates the wash water's exact temperature in both Celsius and Fahrenheit. Manually turn the valves for a steady supply of water to reach the right temperature. A specially designed blending chamber efficiently blends the hot and cold water for maximum performance. The M-159TG mixing station is constructed from Bronze with internal parts made of bronze/stainless steel and is equipped with a solid Stainless Steel hose rack for convenient hose storage. Hose is sold separately. Available options include Wall Mounted (shown), Recessed Wall Box Units, and Pedestal Units.

-

The Strahman M-200 TS is a Thermostatically Controlled Bronze Mixing Unit that allows you to blend hot and cold water to an exact output water temperature. The M-200 TS is accurate and solid. Its liquid-filled thermostat allows you to set your desired output water temperature – anywhere from 80°F to 160°F. This unit includes several important features like a single lever On/Off operation, an adjustable temperature limit stop, and a thermostat that senses and compensates for temperature or pressure fluctuations, all for maximum safety and efficiency. With its durable bronze body construction, this unit is reliable and long-lasting. The valve features replaceable components that resist corrosion, and both the piston and liner are made of stainless steel material for long-lasting durability.

Features:

- Single lever On/Off operation

- Precise temperature control from

- 80°F/27°C to 160°F/71°C

- Adjustable temperature limit stop

- For maximum safety

- Replaceable components facilitate servicing

- Senses and compensates for temperature or pressure fluctuations (up to a 50% drop in inlet supply pressure)

-

Feature

- Thermostatically designed safety shut-off prevents unit from overheating

- Unit automatically compensates for water pressure fluctuations to maintain desired water temperature

- Thermostat is hydraulically formed, liquid-filled bellows

- Removable parts for easy cleanup and inspection

-

The M-5000TG Bronze Mixing Unit produces instant hot water from a steady supply of steam and cold water. Users can easily regulate the temperature by turning the unit’s steam and cold water valves. The unit also features a specially designed blending chamber to thoroughly and evenly blend the steam and cold water. The M-5000TG Series is equipped with a dial-type gauge that accurately indicates the wash water’s exact temperature. As an added safety measure, these units shut off their steam source automatically if the cold water supply falls below 50 PSI for any reason. This prevents hazardous steam from exiting the unit and causing the user steam burns. All units include our patented Direct Diffuse® Steam Trap. Standard Strahman mixing units are constructed from bronze with internal parts made of bronze/stainless steel.

-

Recover expensive water, sewage, and energy utility costs by improving efficiency and reducing water usage--benefit from savings of up to 20%. The M-5144TG HE is high-efficiency steam and cold water mixing station modelled after the standard M-5000 TG mixing station. This is a low-pressure system ideal for industrial wash down where varying water pressures throughout a plant exist and a greater range of adjustable pressure is desired or where the use of a low flow nozzle is the preferred choice. Highly efficient and adaptable when used in combination with our low flow water-saving nozzles such as the M-70 series or S-70 series and a Strahman hose assembly.

-

The M-5700TG Stainless Steel Mixing Unit produces instant hot water from a steady supply of steam and cold water. Users can easily regulate the temperature by turning the unit’s steam and cold water valves. The unit also features a specially designed blending chamber to thoroughly and evenly blend the steam and cold water. The M-5700TG Series is equipped with a dial-type gauge that accurately indicates the wash water’s exact temperature. As an added safety measure, these units shut off their steam source automatically if the cold water supply falls below 50 PSI for any reason. This prevents hazardous steam from exiting the unit and causing the user steam burns. All units now include a Direct Diffuse Steam Trap. The Strahman M-5700TG mixing units are constructed from all stainless steel, so they will not discolour, they are easy to clean, and are ideal for use in special water applications like purified water.

-

Features:

The M-70 Low Flow provides a lower flow option to our standard M-70 Series spray nozzle. By purchasing a Low Flow M-70, you will benefit from reduced water consumption rates, while still getting the same modern and innovative engineering principles and premium quality parts found in all of Strahman’s products. The M-70 Low Flow features all bronze construction, a replaceable heavy-duty rubber cover, stainless steel seat design to prevent leakage, and instant water shut-off when the trigger is released.Water Pressure PSI Low Flow Nozzle 20 2 1⁄4 30 2 3⁄4 40 3 1⁄4 50 3 3⁄4 60 4 1⁄8 70 4 1⁄2 80 4 7⁄8 90 5 100 51⁄8 -

Features:

- Modern and innovative engineering with premium quality parts

- Long handle design grip for whole hand

- Replaceable (heavy duty) renewable rubber cover placement

- Stainless steel seat design prevents nozzle seat leakage

- Instant water Shut-off when the trigger is released

- Spare parts available to service gun

Max. Pressure Max. Flow Max. Temperature 10 BAR 37.5 l/min 93°C - Available in Black, Red and White

- Available ½”, ”, ¾” ID hose barb, or ¾” GHT swivel adapter with locking ring

- 1-year limited warranty

NOTE: Intended for water use only. Not suitable for steam service. Can be used with Strahman steam/water mixers.

Order Part Number Material Colour M-70-BK Bronze Black M-70-RE Bronze Red M-70-WH Bronze White -

The Strahman M-750 Hot & Cold Water Mixing Stations enable the operator to manually regulate water temperature as needed for the washdown application via independent controls. Model M-750 is the economical unit for washdown applications where the precise temperature of hot and cold water is not critical for the application. Manually turn the valves for a steady supply of water. A specially design blending chamber efficiently blends the hot and cold water for maximum performance. The M-750 mixing station is constructed from Stainless Steel with internal parts made of bronze/stainless steel and is equipped with a solid Stainless Steel hose rack for convenient hose storage. Hose and spray nozzle are sold separately. Available options include Wall Mounted (shown), Recessed Wall Box Units, and Pedestal Units.

-

The Strahman M-750TG Hot & Cold Water Mixing Station enables the operator to manually regulate water temperature as needed for the washdown application via independent controls. Model M-750TG is ideal for situations where the exact water temperature is crucial for the washdown application since it is equipped with a dial-type temperature gauge (TG) that indicates the wash water's exact temperature in both Celsius and Fahrenheit. Manually turn the valves for a steady supply of water to reach the right temperature. A specially design blending chamber efficiently blends the hot and cold water for maximum performance. The M-750TG mixing station is constructed from Stainless Steel with internal parts made of bronze/stainless steel and is equipped with a solid Stainless Steel hose rack for convenient hose storage. The hose and spray nozzle are sold separately. Available options include Wall Mounted (shown), Recessed Wall Box Units, and Pedestal Units.

-

CIP spray nozzles designed to provide superior tank cleaning results at low operating pressures. Your solution to cleaner tanks with less water. Use M-SERIES tank washers with patented Flow Step Technology as a direct replacement for spray balls, delivering more efficient spray distribution, greater impact and faster C.I.P cycles. This means less waste water and low-chemical treatment costs, saving you time and money.